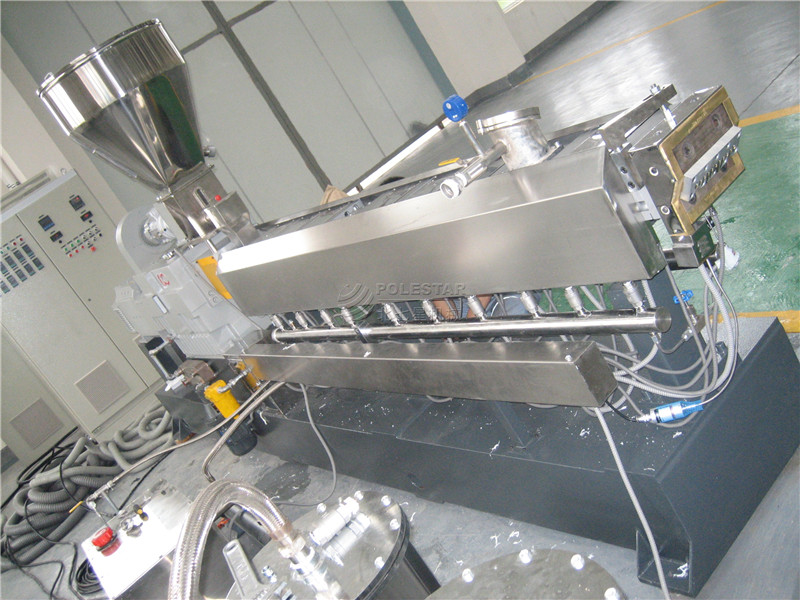

Kiekie Efficient PET Granulating Machine

Nā hiʻohiʻona

ʻO ka pelletizer PET ka mea nui e nā mea hana penei: extruder, hydraulic screen changer, strand cutting mold, cooling conveyor, dryer, cutter, fan blowing system (feeding and drying system), etc. , puka kiʻekiʻe me ka hoʻohana mana haʻahaʻa.

Palapala noi

Hoʻohana ʻia ka mīkini pelletizing pet e hana i ka pellet plastic flakes i loko o ka pellet a i ʻole granule.Twin screw extruder recycling & pelletizing system i hoʻopili ʻia i nā mea ʻōpala, pono ka hana kiʻekiʻe o ka hoʻoheheʻe ʻana, volatilization, kānana etc.

Kaʻina Hana

Mea hānai wili ( OPTIONAL) → Mea hānai ikaika → Extruder māhoe māhoe like → Hoʻololi kānana hydraulic → Poʻo poʻo → pahu hoʻoluʻu wai → ʻoki maʻamau maʻamau → Hoʻopili ʻia ka huahana.

Ka wehewehe kikoʻī o kēlā me kēia mea

1. Mea hānai Screw: lawe i nā ʻōpala Plastic i loko o ka mīkini nui.

2. Mea hānai ikaika: mea hānai meaʻai i extruder me ka wikiwiki i hoʻolālā ʻia, hiki ke hoʻololi i ka wikiwiki.

3. Māhoe māhoe wili extruder: plasticizing mea a me ka luhi kinoea.

4. High-wikiwiki Net hoʻololi nenoaiu a me Die-poʻo: kānana mea haumia, e hana i oi paʻa.

5. ʻO ka pahu wai: hoʻoluʻu i nā noodles PET.

6. ʻOki maʻamau maʻamau: ʻoki i nā noodles PET i loko o nā granuels.

Pōmaikaʻi hoʻokūkū

1. Mana PLC 'akomi

2. Me ka hoʻomalu wela hoʻokahi

3. Hana maʻalahi & hana paʻa

4. ʻOi aku ka maikaʻi, palekana kaiapuni a me ka mālama ʻana i ka ikehu

ʻIkepili ʻenehana

| Extruder | TSK35 | TSK50 | TSK60 | TSK65 | TSK75 | TSK95 |

| L/D(mm) | 24-56 | 24-56 | 24-56 | 24-56 | 24-56 | 24-56 |

| Māmā (rpm) | 600 | 500 | 300-500 | 400-500 | 400-500 | 300-400 |

| Mana Mana (kw) | 11-18.5 | 22-37 | 37-55 | 45-75 | 90-160 | 185-250 |

| Ka mana hoʻomehana (kw) | 16 | 24 | 30 | 34 | 45 | 60 |

| Hualoaʻa Max (kg/h) | 20-80 | 50-200 | 80-300 | 100-350 | 200-500 | 700-1200 |

Māhele huahana

Makemake ʻoe e hoʻohui i ka lani i kāu hoʻolālā?

E kelepona mai iā mākou i kēia lā no kahi kūkākūkā hoʻolālā.